Heat Pump

Our common future needs new technologies

Heat Pump

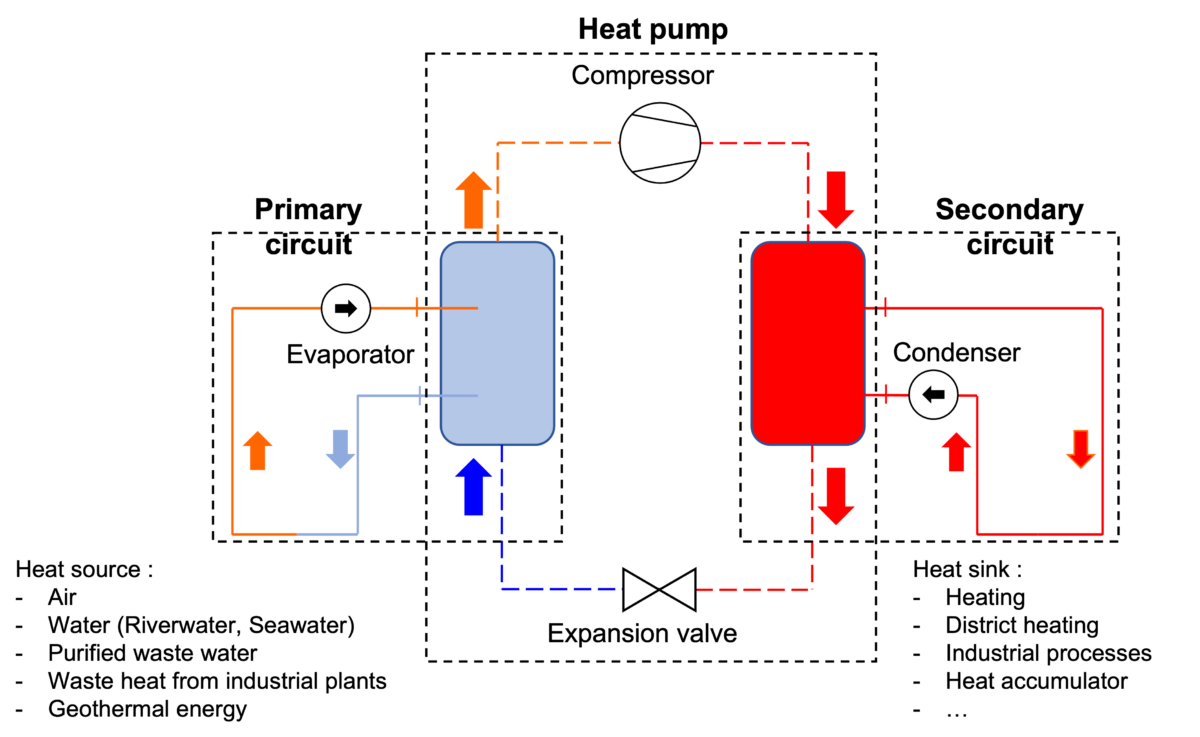

Heat pumps transfer low-temperature heat from the environment and waste heat from industrial processes as useful heat at a higher temperature level to a system to be heated. A heat pump has a primary and a secondary circuit. Heat is transferred from the primary to the secondary circuit via two heat exchangers by a refrigerant circulating in the heat pump.

Primary circuit

The primary circuit is the circuit that brings the thermal energy into the heat pump and heats the refrigerant via a heat exchanger.

Secondary circuit

In the secondary circuit, the heat stored in the refrigerant is transferred via a heat exchanger to the medium circulating in the secondary circuit.

Basic principle

Large heat pump (LHP)

Large heat pumps can transmit outputs of several MW.

Large heat pumps from approx. 2 MW are custom-made products that are specially designed and manufactured to meet the requirements of the application. In many projects, the large heat pump is part of an overall system, such as in a district heating network, in combination with combined heat and power plants or P2H processes.

Due to the project-specific requirements when using large heat pumps, timely and detailed planning is necessary. This applies not only to the design of the large heat pump, but also to the planning of the primary and secondary circuits of the entire system.

The DSD's scope of services includes:

- Feasibility and concept studies

- Support with approval planning

- Project planning and project management of GWP projects

- Planning, calculation and construction of the GWP complete system

- Delivery and installation of the GWP plant technology

- Measurement and control technology of the GWP plant

- Mechanical and electrical installation

- Assembly and assembly supervision

- Commissioning and trial operation

- Maintenance and service

As a general contractor (EPC), DSD offers you turnkey technical solutions adapted to customer requirements. DSD works together with renowned suppliers for this purpose.