Our

core competencies

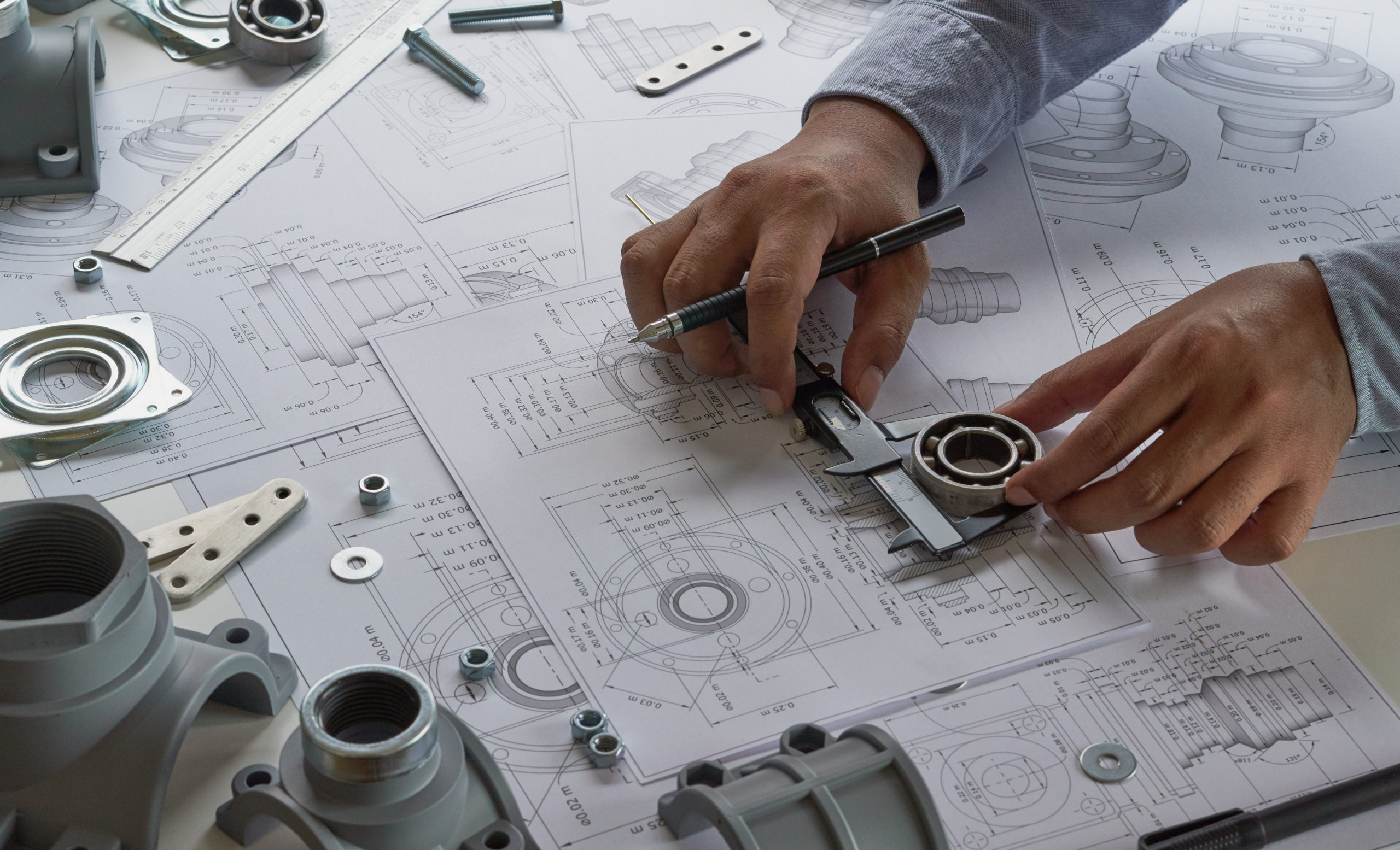

DSD Power Technologies GmbH offers you all competencies from a single source.

Engineering

-

Consulting

-

Preparation of studies for optimization of power plant processes

-

Planning of complete plants

-

Approval planning

-

Basic and detail engineering

-

Cycle calculations of power plant processes

-

Thermal calculation of steam generators

-

Burner design (measures for NOx reduction)

-

Fuel change

-

Optimization of grinding plants

-

Service life extension

-

Optimization of steam generators (efficiency increase)

-

Optimization of start-up and shut-down processes

-

Welding technology

-

Measures for air pollution control, dust removal, NOx reduction

-

Heat utilization systems

-

Conveyor technology

-

Electrical engineering

Project management / General contractor

-

Project planning (tender project planning, layout planning)

-

Approval planning

-

Basic, detail engineering

-

Overall scheduling

-

Production and schedule control

-

Contract awarding to subcontractors

-

Commercial project management / controlling

-

Site management

-

Electrical and control technology

-

Quality management

-

Auditing of subcontractors

-

Deadline tracking

-

Quality assurance

-

Commissioning

Powert to Heat

-

Engineering, supply, installation, commissioning of P2H plant

-

Electrode boilers for hot water production

-

Electrode boilers for saturated steam generation

-

Electrode superheater for superheated steam generation

-

Heat pump system, including integration into the plant system

Maintenance and repair in power plant construction

-

Planning and execution of complex revisions in power plants and industrial facilities

-

Supply and production supervision

-

Supply of required spare parts

-

Execution of assembly services

-

Quality assurance

-

Ensuring occupational safety

-

Preparation of documentation

Measures take place specifically in the area:

- Pressure parts and piping

- Firing and ash removal systems

- Service on grinding plants

Relocation

-

Modern coal and gas-fired power plants with sound performance record as complete service incl. recommissioning and proof of performance

-

Service life comparable to new plants after rehabilitation (in the course of implementation)

-

60-70% investment costs compared to new plant

-

Shorter payback period

-

Lower investment risk

-

Adaptation to new site conditions

-

Evaluation / assessment of the old plant